Taxiway lighting is essential for safe aircraft movement on the ground during low visibility or nighttime operations. According to ICAO Annex 14 – Volume I (Aerodrome Design and Operations), the types of taxiway lights vary in size, color, placement, operation, manufacturer standards, and spacing. Here’s a breakdown based on ICAO standards:

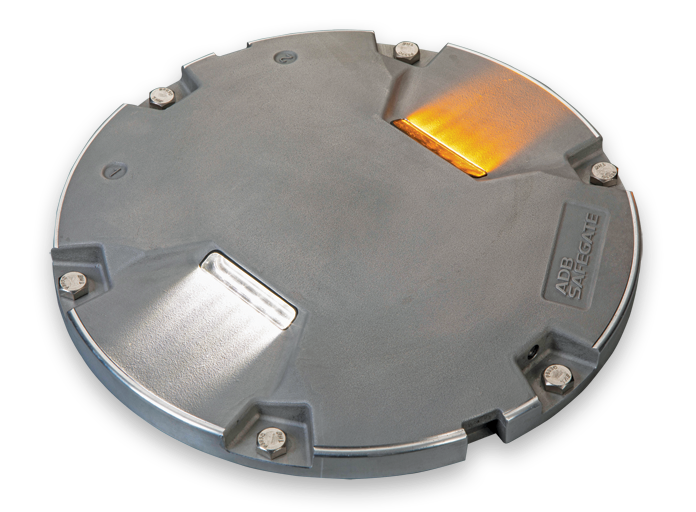

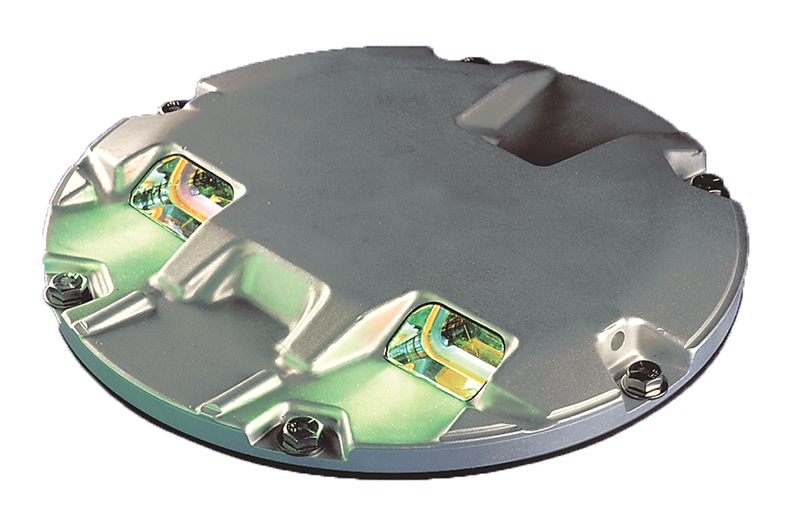

Taxiway Centerline Light (TXC)

- Type: Inset Light

- Size: 8”

- Mounting: Inset

- Spacing: 7.5 / 15 meters (as per ICAO recommendations)

- Color: Green / Yellow (typically green along straight sections, yellow before runway-holding positions)

- Manufacturers:

- ADB SAFEGATE

- OCEM

- Hella

Template for Remaining Taxiway Lights

Taxiway Edge Light (TXE)

- Type: Elevated or inset

- Size: (Usually 12″ for elevated / 8″ for inset)

- Spacing: Typically 60 meters or as per design

- Color: Blue

- Manufacturers:

- ADB SAFEGATE

- OCEM

- Hella

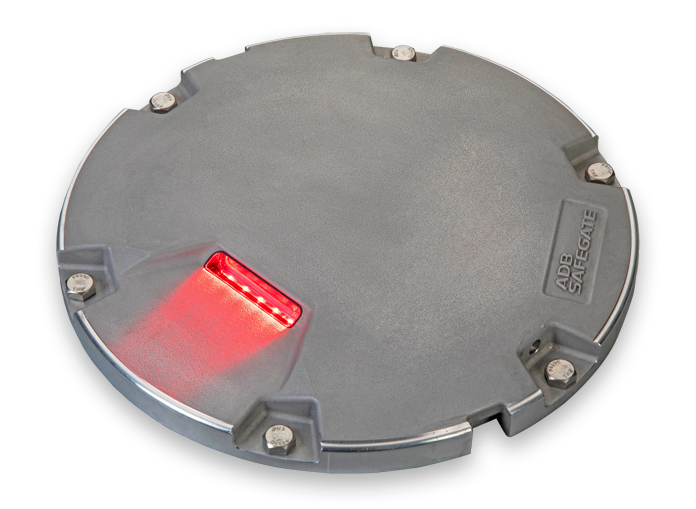

Taxiway Stop Bar Light (TXS)

- Type: Inset

- Size: 12”

- Spacing: 3 meters between lights along the bar

- Color: Red

- Manufacturers:

- ADB SAFEGATE

- OCEM

- Hella

Runway Guard Light (RGL / WIG-WAG)

- Type: Elevated flashing lights

- Spacing: As per standard (typically paired on either side of a taxiway/runway intersection)

- Color: Yellow (flashing)

- Manufacturers:

- ADB SAFEGATE

- OCEM

- Hella