Steps of Design

- Defining our loads.

- Sizing inverter.

- Sizing panels.

- Sizing batteries.

- Sizing a charge controller.

- Panel connection.

Step 1: Defining our Loads

| Device | Number | Power/device(w) | Number of Hours | Energy (wh) |

| Lamp | 1 | 18 w | 4 | 72 wh |

| Fan | 1 | 60 w | 2 | 120 wh |

| Refrigerator | 1 | 75 w | 12 | 900 wh |

| Total | 153 w | 1092 wh/day |

Step 2: Sizing Inverter

- An inverter is used in the system where AC power output is needed.

- The input rating of the inverter should never be lower than the total wattage of appliances.

- The inverter must have the same nominal voltage as your battery.

- For stand-alone systems, the inverter must be large enough to handle the total amount of watts you will be using at one time.

- For grid-tie systems or grid-connected systems, the input rating of the inverter should be the same as the PV array rating to allow for safe and efficient operation.

- The inverter power should be greater than the load’s total wattage by 25% or 30%.

- The inverter’s continuous power = 1.3* total wattage = 1.3153 W = 198.9 W.

- If the system has motors, compressors, refrigerators, pumps, and washing machines, we need to make sure that the inverter can withstand the starting current.

- The surge power of these devices is found on the label of them.

- If you don’t know, you can assume the surge power = 3x – 4x the wattage of these devices.

- The inverter surge power = Lamp + Fan + 4 Refrigerators = 378 W.

- We need an inverter with a continuous power of 198.9 W and a surge power of 378 W.

Step 2: Sizing Inverter

Step 3: Sizing Panels

- The total energy required by the loads is 1092 Wh/day.

- The total energy needed from panels = total energy * 1.3 (a safety factor to accumulate for all the losses in the PV system in addition to the panels not operating at the optimum conditions) = 1092 Wh * 1.3 = 1419.6 Wh.

- The power of panels = 𝑇𝑜𝑡𝑎𝑙 𝑒𝑛𝑒𝑟𝑔𝑦 𝑛𝑒𝑒𝑑𝑒𝑑 𝑝𝑒𝑎𝑘 / 𝑠𝑢𝑛 ℎ𝑜𝑢𝑟𝑠

- = 1419.6𝑊ℎ2 ℎ𝑜𝑢𝑟𝑠 = 709.8W.

- We will select Sunpower SPR-200-BLK-U.

- Number of panels = 𝑇𝑜𝑡𝑎𝑙 𝑝𝑜𝑤𝑒𝑟 / 𝑝𝑜𝑤𝑒𝑟 𝑜𝑓 𝑜𝑛𝑒 𝑝𝑎𝑛𝑒𝑙

- =709.8200=3.549 𝑜𝑟 𝑎𝑝𝑝𝑟𝑜𝑥𝑖𝑚𝑎𝑡𝑒𝑙𝑦 4 𝑝𝑎𝑛𝑒𝑙𝑠.

- The power of panels = 4 * 200 = 800 W.

Step 4: Sizing Batteries

- Assuming the lowest temperature in the location is -20°C. Then the nominal capacity will be 160 Ah instead of 330 Ah.

- The temperature correction coefficient = 160𝐴ℎ / 330𝐴ℎ=0.48.

- Ah of batteries = 𝑇𝑜𝑡𝑎𝑙 𝑒𝑛𝑒𝑟𝑔𝑦 𝑛𝑒𝑒𝑑𝑒𝑑∗𝐷𝑎𝑦𝑠 𝑜𝑓 𝑎𝑢𝑡𝑜𝑛𝑜𝑚𝑦 / 𝐷𝑜𝐷∗𝑆𝑦𝑠𝑡𝑒𝑚 𝑣𝑜𝑙𝑡𝑎𝑔𝑒∗𝑇𝑒𝑚𝑝𝑒𝑟𝑎𝑡𝑢𝑟𝑒 𝑐𝑜𝑟𝑟𝑒𝑐𝑡𝑖𝑜𝑛 𝑐𝑜𝑒𝑓𝑓𝑖𝑐𝑖𝑒𝑛𝑡

- = 1419.6𝑊ℎ∗2 / 0.8∗12𝑉∗0.48

- = 616.15 Ah.

- Number of series batteries = 𝑆𝑦𝑠𝑡𝑒𝑚 𝑣𝑜𝑙𝑡𝑎𝑔𝑒 / 𝑏𝑎𝑡𝑡𝑒𝑟𝑦 𝑣𝑜𝑙𝑡𝑎𝑔𝑒 = 12/12 = 1 𝑏𝑎𝑡𝑡𝑒𝑟𝑦 𝑖𝑛 𝑒𝑎𝑐ℎ 𝑠𝑒𝑟𝑖𝑒𝑠 𝑠𝑡𝑟𝑖𝑛𝑔.

- Number of parallel strings = 𝐴ℎ 𝑟𝑒𝑞𝑢𝑖𝑟𝑒𝑑 / 𝐴ℎ 𝑜𝑓 𝑜𝑛𝑒 𝑏𝑎𝑡𝑡𝑒𝑟𝑦=616.15 / 330=1.86 𝑜𝑟 𝑎𝑝𝑝𝑟𝑜𝑥𝑖𝑚𝑎𝑡𝑒𝑙𝑦 2 𝑝𝑎𝑟𝑎𝑙𝑙𝑒𝑙 𝑠𝑡𝑟𝑖𝑛𝑔𝑠.

- Total batteries = 2*1 = 2 batteries.

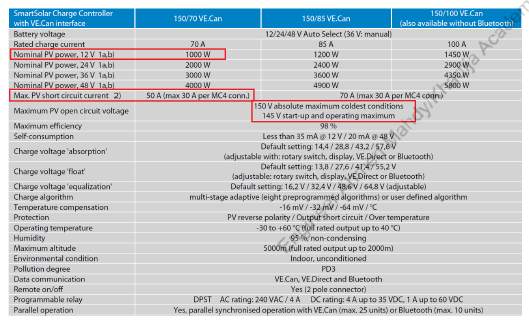

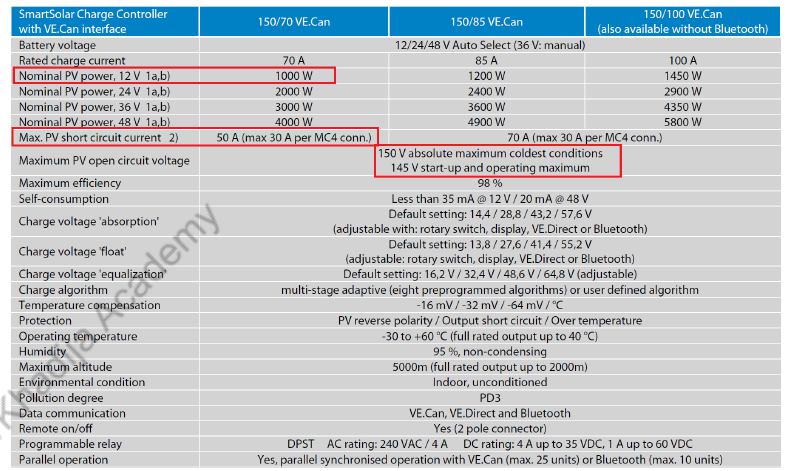

Step 5: Sizing Charge Controller

- The power of panels = 800 W and the system voltage is 12 V.

Important Note:

- The series panel connection is dependent on the MPPT range.

- We try to make the panel voltage at the middle value of this range.

- If the MPPT range is not available, we will take half of the open circuit voltage value.

Step 6: Panel Connection

- Assuming selection of the open circuit voltage at the middle of the maximum PV open-circuit voltage = 150/2=75 𝑉.

- Number of panels in series = 𝐷𝑒𝑠𝑖𝑔𝑛 𝑜𝑝𝑒𝑛 𝑐𝑖𝑟𝑐𝑢𝑖𝑡 𝑣𝑜𝑙𝑡𝑎𝑔𝑒 / 𝑃𝑎𝑛𝑒𝑙 𝑜𝑝𝑒𝑛 𝑐𝑖𝑟𝑐𝑢𝑖𝑡 𝑣𝑜𝑙𝑡𝑎𝑔𝑒

- =75 𝑉 / 47.8 𝑉=1.57 𝑜𝑟 𝑎𝑝𝑝𝑟𝑜𝑥𝑖𝑚𝑎𝑡𝑒𝑙𝑦 2 𝑝𝑎𝑛𝑒𝑙𝑠 𝑖𝑛 𝑠𝑒𝑟𝑖𝑒𝑠.

- Panels in parallel = 𝑇𝑜𝑡𝑎𝑙 𝑛𝑢𝑚𝑏𝑒𝑟 𝑜𝑓 𝑝𝑎𝑛𝑒𝑙𝑠 / 𝑛𝑢𝑚𝑏𝑒𝑟 𝑜𝑓 𝑝𝑎𝑛𝑒𝑙𝑠 𝑖𝑛 𝑠𝑒𝑟𝑖𝑒𝑠=4/2=2 𝑝𝑎𝑟𝑎𝑙𝑙𝑒𝑙 𝑠𝑡𝑟𝑖𝑛𝑔𝑠.

- The open circuit voltage at lowest temperature = number of series panels * open circuit voltage of one panel at lowest temperature.

- = 2(47.8+(0.065*(25+20))=101.45V < 150 V.

- The input current of the charge controller = short-circuit current of the PV panel * number of parallel strings * safety factor (1.25 or 1.3).

- = 1.2525.4 = 13.5 A < 50 A

Electrical electrical technician

Bms

1 electrical